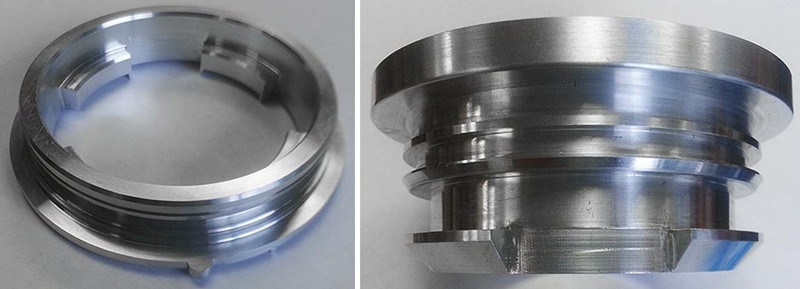

High Precision Yakarasika Wax Steel Casting

Product Description

Simbi isina nguraisimbi alloy ine hushoma hwe10.5% chromium yemukati nekuwanda.Stainless simbi inoshandiswa apo zvose zvinhu zvesimbi uyecorrosion resistancezvinodiwa.Saka semamwe akakandwa simbi alloys, Stainless simbi inoshandiswa zvakanyanya kukanda kugadzirwa.

Stainless simbi yekukandira yakagadzirwa musimbi yedu foundry inonyanya nasilical sol castingprocess.Silica sol casting ndiyo yakanyanyaprecision investment castingprocess.Stainless simbi yekukanda maitiro inosanganisira kunyunguduka kwesimbi, kuumba, uye kugadzira zvinhu zvemhando yepamusoro nekudziya nguva dzose kana kuchenesa.Kana zvinhu zvakajairwa zvekukandira zvisingakwanise kuunza simba rakakwana uye zvisingaite maficha ipapo simbi isina tsvina inongotorwa sarudzo inoshamisa pane vamwe.Iyi nzira inogona kuburitsa yakakwirira chaiyo net chimiro castings pasina machining.Kazhinji isu tinokwanisa kudzora yakadaro chaiyo Stainless simbi kukanda nekushivirira CT5-6 level.Imwe bhenefiti ndeyekuti, nemaitiro aya, chivakwa chedu chinogona kupa Stainless simbi yekukandira isina hurema.

Common Material Magiredhi eStainless Steel Casting

SS304:Iyo inonyanya kushandiswa austenite simbi, inogona kunzi A2 isina tsvina.

SS316:Yechipiri yakajairika austenite simbi, inonziwo A4 isina tsvina.SS316 inoshandiswa zvakanyanya nekuda kwekuwedzera kwayo kuramba kune ngura.

SS304L uye SS316L(superaustenitic Stainless steel): Iyo [L” inoreva kuti kabhoni yemukati meiyo alloy iri pazasi 0.03%, izvo zvinoderedza kunzwisiswa kunokonzerwa nekupisa kwakanyanya kunowanikwa mukunama.Enzanisa ne300 akatevedzana, inoratidza kuramba kuri nani kushushikana-kukoromoka kutsemuka.

17-4 PH:Kunyanya kunaya kwemvura-kuomesa martensitic simbi isina tsvina, inoshandisa inenge 17% chromium uye 4% nickel.

Surface Kurapa kweStainless Simbi Castings

Shot Blasting: Inoshandiswa kubvisa ganda dema oxide mushure mekukanda zvigadzirwa zvesimbi isina tsvina.

Pickling & Passivation Kurapa: Pickling ikemikari yekurapa nzira yekubvisa tsvina yepamusoro senge oxide ganda, ngura, welding nzvimbo, ect.Uye passivation inzira inoumba itsva yakawanda yakawanda chromium inodzivirira, nekudaro kuvandudza iyo anti-oxidation kugona kwesimbi isina tsvina.

Electropolishing: Inoshandiswa kubvisa pamusoro diki burrs uye kunatsiridza kupenya kweStainless simbi castings.

Mirror Polishing: Rudzi rwekupenya kwepamusoro nzira inogona kuwana yakatsetseka uye inopenya senge girazi kupera.

Kushandiswa kweStainless Steel Castings

Kune iyo yakasarudzika yemuviri zvimiro zveStainless simbi, Stainless simbi castings inoshumirwa kune dzakasiyana siyana maindasitiri, kunyanya ayo ari munzvimbo dzakaomarara.Pazasi pane mashandisirwo makuru ekukanda simbi isina tsvina

fekitari yedu