Titanium alloy zvikamu tirakita Chikamu/Simbi Jecha Machina/Simbi Yakagadzirwa/Mechanical/Mota Zvikamu zveCompressor Muviri

| Material | Aluminium: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| Simbi isina tsvina: SS201, SS301, SS303, SS304, SS316, SS430 nezvimwe. | |

| Simbi: nyoro simbi / kabhoni simbi kusanganisira 1010, 1020, 1045, 1050, Q690 etc. | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 nezvimwe. | |

| Mhangura: C11000, C12000, C12000, C17200, C72900, C36000 nezvimwe. | |

| Processing | Germany Trumpf brand Laser cutter, CNC yekugera muchina, CNC bending muchina, |

| (CNC) chidhindo muchina, Hyraulic Machine, Yakasiyana-siyana welding muchina, CNC muchina centre. | |

| Surface | Aluminium: Anodization, Sandblast, Brushing, Polishing, Electro-plating etc |

| Stainless Simbi: Kupukuta, Kukwesha, Kupfuudza, Sandblasting, Electro-plating | |

| Simbi: Zinc plating, nickel plating, Chrome plating, Powder Coating, Painting nezvimwe. | |

| Brass & Copper: Kukwesha, kupukuta nezvimwe | |

| Precision | + - 0.1mm |

| Application | Chitima, Auto, Rori, Kurapa, Michina, Equipment, Electronic, Magetsi etc |

Titanium rudzi rutsva rwesimbi.Kuita kwetitanium kune hukama nezviri mukati metsvina senge kabhoni, nitrogen, hydrogen uye oxygen.Zviri mukati metsvina mu purest titanium iodide iri pasi pe0.1%, asi simba rayo rakaderera uye plasticity yakakwira.Zvinhu zve99.5% industry pure titanium ndezvizvi: density ρ=4.5g/cm3, melting point 1725℃, thermal conductivity λ=15.24W/(mK), kusimba kwesimba σb=539MPa, kurebesa δ=25%, shrinkage yechikamu ψ=25%, modulus ye elasticity E=1.078×105MPa, kuoma HB195.

Simba repamusoro

The density yetitanium alloy inowanzoita 4.51g/cm3, 60% chete yesimbi, uye mamwe akasimba etitanium alloys anopfuura simba reakawanda alloy structural steels.Naizvozvo, iyo chaiyo simba (simba/density) yetitanium alloy yakakura kwazvo. kupfuura iyo yezvimwe zviumbwa zvesimbi, izvo zvinogona kubudisa zvikamu zvine simba guru reyuniti, kusimba kwakanaka uye kureruka kurema.Aircraft engine components, skeleton, ganda, fasteners uye giya rekumhara zvose zvinoshandisa titanium alloy.

Kuwedzera kupisa simba

Iyo tembiricha yekushandisa imazana mashoma madhigirii akakwira kupfuura aruminiyamu alloy, anogona kuramba achichengetedza simba rinodiwa ari pakati tembiricha, anogona kushanda kwenguva yakareba pa 450 ~ 500 ℃ tembiricha.Mhando mbiri idzi dzetitanium alloy mu 150 ℃ ~ 500 ℃ range richine simba rakanyanya rakananga, uye aruminiyamu alloy pa 150 ℃ simba chairo rakadzikira zvakanyanya.Tembiricha yekushanda yetitanium alloy inogona kusvika 500 ℃, nepo iyo yealuminium alloy iri pazasi. 200 ℃.

Kuramba kwakanaka kune ngura

Kudzivirirwa kwekuora kwetitanium alloy kuri nani pane kuya kwesimbi isina simbi mumhepo yakanyorova uye mumvura yegungwa. Pitting corrosion, acid corrosion, stress corrosion resistance yakanyanya kusimba;Inodzivirira kugwinya kwakanaka kune alkali, chloride, chlorine organic products, nitric acid. , sulfuric acid, etc.Asi kurwisana kwekuora kwetitanium kuderedza oksijeni uye chromium medium haina kunaka.

Good low temperature performance

Titanium alloy inogona kuchengetedza maitiro ayo emagetsi pane yakaderera uye yakanyanya-yakaderera tembiricha.Titanium alloys ine yakanaka yakaderera tembiricha performance uye yakadzika kwazvo interstitial elements, senge TA7, inogona kuchengetedza imwe plasticity pa -253 ℃.Naizvozvo, titanium alloy yakakoshawo. yakaderera tembiricha structural zvinhu.

High chemical activity

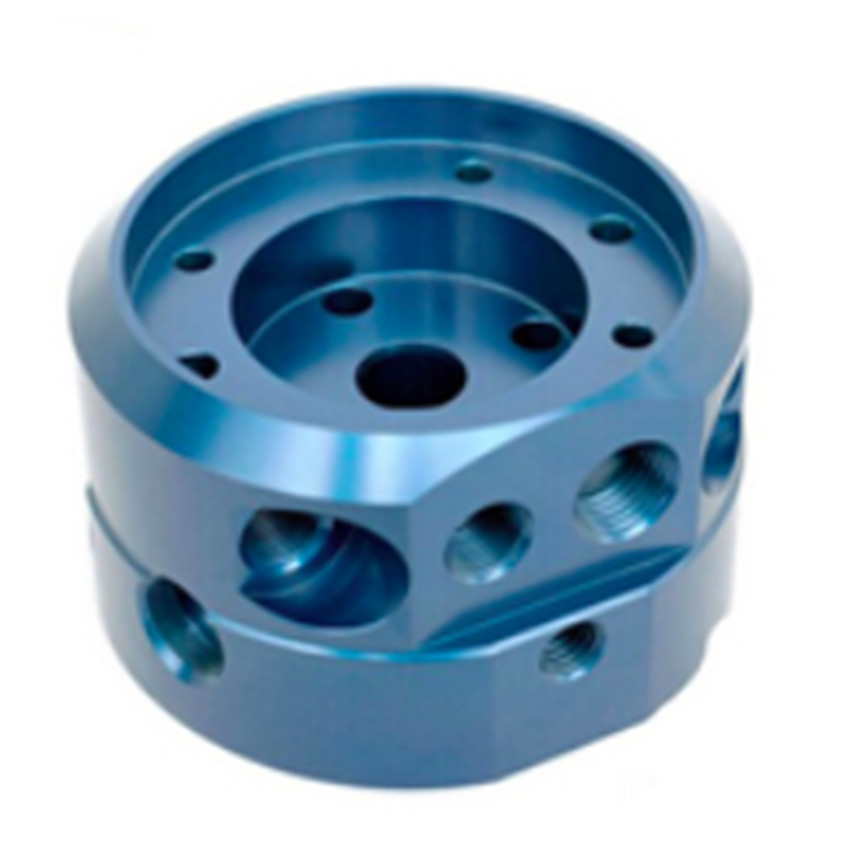

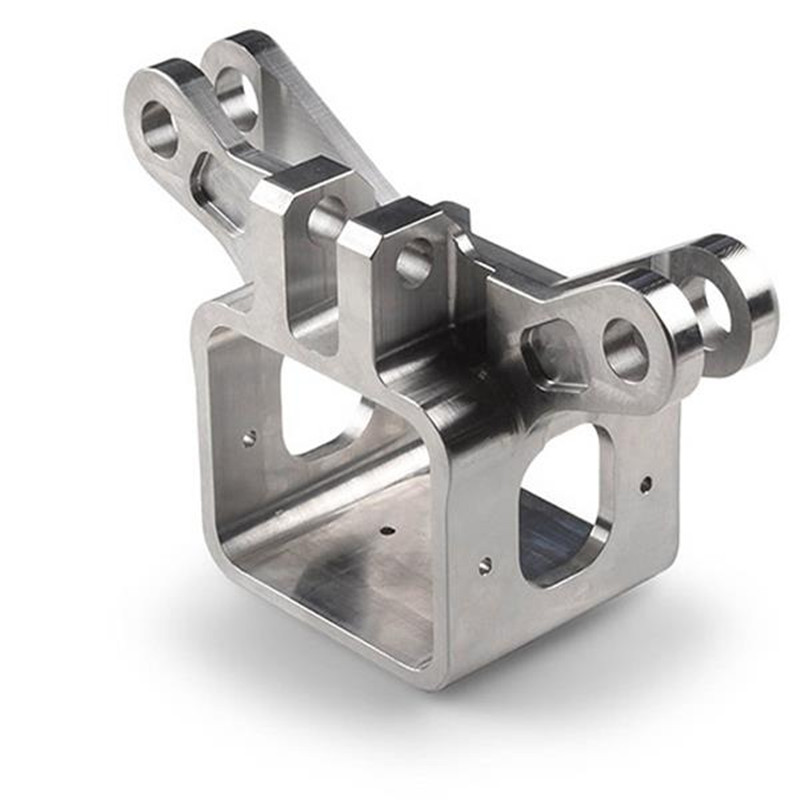

Titanium alloy zvigadzirwa

Titanium alloy zvigadzirwa

Titanium ine simba remakemikari rinosangana neO2, N2, H2, CO, CO2, mhute yemvura, ammonia nemamwe magasi ari mumhepo.Kana iyo carbon content yakakura kudarika 0.2%, yakaoma TiC ichaumbwa mu titanium alloy. tembiricha yakakwira, iyo yakaoma nzvimbo yeTiN ichaumbwa nekudyidzana neN. Kana tembiricha iri pamusoro pe600 ℃, titanium inotora oxygen uye inoita dhiza rakaoma nekuoma kwakanyanya. uyewo kuumba.Kudzika kweiyo yakaoma uye brittle surface layer inogadzirwa nekutora gasi inogona kusvika 0.1 ~ 0.15 mm, uye dhigirii yekuomesera ndeye 20% ~ 30%. pamusoro.

Small thermal conductivity elasticity

Thermal conductivity yetitanium (λ=15.24W/(m·K)) ingangoita 1/4 yenickel, 1/5 yesimbi, 1/14 yealuminum, uye kupisa kwekupisa kwetitanium dzakasiyana siyana. alloys inenge 50% yakaderera pane iyo yetitanium.Iyo elastic modulus yetitanium alloy inenge 1/2 yesimbi, saka kusimba kwayo kwakashata, nyore kushanduka, haifaniri kugadzirwa netsvimbo yakatetepa uye zvikamu zvakatetepa-masvingo, kucheka kana. kugadziridzwa kwepamusoro peiyo rebound yakakura, inenge 2 ~ 3 nguva yesimbi isina tsvina, zvichiita kuti pave nekukakavadzana kwakanyanya, kunamatira, kupfeka kupfeka pamusoro pekushandisa.